3-D printing, also known as additive manufacturing, makes three-dimensional objects with machines that are controlled by specialized computer programs. Scientists have used the technology of 3-D printing to create everything from life-like prosthetics to teeth and bones, making many medical practices faster and more personalized. Though 3-D printing is still used predominantly in the automobile and aerospace industries, ideas for its usage in other fields are cropping up and providing inspiration for the future. In fact, it may not be too long before entire human organs can be produced in this fashion.

In order to use 3-D printing for the purpose of creating human tissue, scientists must overcome many challenges. Researchers have already worked through some of these difficulties, but there are many more to contend with as the technology advances. One such challenge is the problem of living cell differentiation and arrangement, that is, now the cells know what type of cells to become or how to situate themselves in relation to other cells. Another challenge is providing for the biological needs of the human cells during the manufacturing process.

Biological 3-D printing work is complex, but scientists and researchers have carefully found ways to avoid some of the problems that come with such a mechanism. The machines involved in 3-D printing have the ability now to arrange cells, often grown from biopsies or stem cells, by type in a three-dimensional structure. The cells then begin to fuse together and chemically signal to one another as they would in the body. One of the problems that remains is the process of circulation, which would normally be needed for any major organs in the body, but scientists are addressing these concerns as they explore new tissues to create.

Tech companies have taken on the challenge as well, privatizing research in order to turn potential finds into a commodity. A good example of this is Organovo, a biotech firm based in California that is producing liver tissue to sell to scientists. Though they cannot make entire functioning livers, this is a step in the right direction.

“[Scientists] can’t do the kind of experiments on a person that they can do with this tissue in a lab setting,” Executive Vice President of Organovo Michael Renard said, discussing the benefits of being able to use liver tissue as a laboratory tool. For ethical reasons, it is not always possible to do experimental procedures on human test subjects. This issue might be avoided with tissue production such as this.

Other research groups at institutions such as Harvard Univeristy and the University of Louisville are trying to create other organs, such as kidneys and even hearts. Though it may be some years before the technology is able to produce fully functioning organs, it certainly seems to be on the horizon.

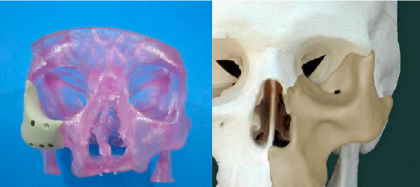

In the meantime, people’s lives are being changed through the increasingly simple production of prosthetic limbs. Better and more personalized hip joint replacements have already been created and used, along with jaw bones, pelvic bones, teeth, and now, even a new face for someone who needs facial reconstruction.

Suzanne Verma, an assistant professor at Texas A&M University Baylor College of Dentistry, recently created an extremely lifelike facial prosthetic based on 3-D imaging technology for a man whose face was damaged by a fungal infection. The merging of the imaging and printing technologies allowed for a prosthetic that strongly resembled his original features.

As breakthroughs like this continue to occur, the possibilities for 3-D printing will begin to seem even more endless than they already are. Perhaps even organ donation will someday become obselete.